Frontiers in Technology

Poster Session A

(1042-A) High-Throughput Parallel Digital Light Processing 3D Bioprinting on the Droplet Microarray

Tuesday, May 28, 2024

16:30 - 17:15 CEST

Location: Exhibit Hall

Julius Von Padberg

Ph. D. researcher

Karlsruhe Institute of Technology

Karlsruhe, Baden-Wurttemberg, Germany

Poster Presenter(s)

Abstract: 3D bioprinting on liquid handling platforms like microwell plates is mainly performed using serial printing technologies, which only allow to print one construct at a time. In serial line-wise deposition, 3D printing and traversing between compartments contribute to the total processing time, which is the sum of individual structure printing times multiplied by the number of compartments to be printed on. A cost intensive way to accelerate the serial process is by using multiple printheads in a layout dictated by the platform to be 3D printed on. Applying parallel 3D printing technologies on liquid handling platforms poses a challenge. The reason is the physical borders between each volume required on most platforms for the compartmentalization of liquids.

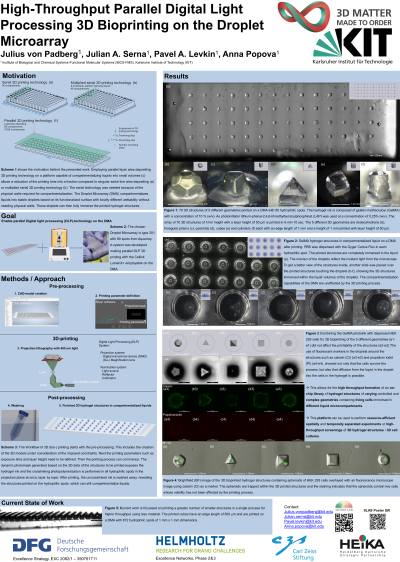

Here, we introduce a new method for parallel 3D bioprinting on the Droplet Microarray (DMA), a liquid handling platform based on a surface patterned glass slide in the object carrier format, comprised of hydrophilic spots separated by a superhydrophobic background. Based on the locally different wettability on the platform’s surface, liquids are being compartmentalized in stable droplets without physical walls in between them. This enables the application of parallel layer-wise depositing 3D printing technologies on all compartment floors in a single printing step. A system was designed, iteratively optimized and manufactured by rapid prototyping to guarantee compatibility with a commercial bioprinter. The setup allows for simple insertion, secure retention, and seamless removal of the DMA. It positions and aligns the DMA during the process. This makes the employment of parallel digital light processing (DLP) technology possible on the DMA.

We demonstrate that through the employment of parallel DLP technology on the DMA the process enables parallel 3D bioprinting of at least 70 cell-laden hydrogel structures in 2 minutes. This truly parallel printing time is equivalent to only one structure in series. Afterwards, liquids can be compartmentalized in each hydrophilic spot, fully immersing the printed cell laden 3D hydrogel structures in stable droplets. This method allows for the formation of an on-chip library of hydrogel structures with different geometries containing living cells immersed in different liquid microcompartments. The combination of miniaturized cell culture compartments with the rapid fabrication of 3D microstructures of varying controlled and complex geometries containing live cells can be used as a platform to carry out resource efficient spatially and temporally separated experiments or screenings in a high throughput fashion.

.

Here, we introduce a new method for parallel 3D bioprinting on the Droplet Microarray (DMA), a liquid handling platform based on a surface patterned glass slide in the object carrier format, comprised of hydrophilic spots separated by a superhydrophobic background. Based on the locally different wettability on the platform’s surface, liquids are being compartmentalized in stable droplets without physical walls in between them. This enables the application of parallel layer-wise depositing 3D printing technologies on all compartment floors in a single printing step. A system was designed, iteratively optimized and manufactured by rapid prototyping to guarantee compatibility with a commercial bioprinter. The setup allows for simple insertion, secure retention, and seamless removal of the DMA. It positions and aligns the DMA during the process. This makes the employment of parallel digital light processing (DLP) technology possible on the DMA.

We demonstrate that through the employment of parallel DLP technology on the DMA the process enables parallel 3D bioprinting of at least 70 cell-laden hydrogel structures in 2 minutes. This truly parallel printing time is equivalent to only one structure in series. Afterwards, liquids can be compartmentalized in each hydrophilic spot, fully immersing the printed cell laden 3D hydrogel structures in stable droplets. This method allows for the formation of an on-chip library of hydrogel structures with different geometries containing living cells immersed in different liquid microcompartments. The combination of miniaturized cell culture compartments with the rapid fabrication of 3D microstructures of varying controlled and complex geometries containing live cells can be used as a platform to carry out resource efficient spatially and temporally separated experiments or screenings in a high throughput fashion.

.