Frontiers in Technology

Poster Session B

(1107-B) Automation of Qiagen’s Miniprep Plasmid Purification Process

Wednesday, May 29, 2024

10:30 - 11:15 CEST

Location: Exhibit Hall

Natalie Isobel Barker, MSc Molecular Genetics and Diagnostics, BSc Forensic Science (she/her/hers)

Laboratory Automation Engineer

AstraZeneca

Cambridge, England, United Kingdom

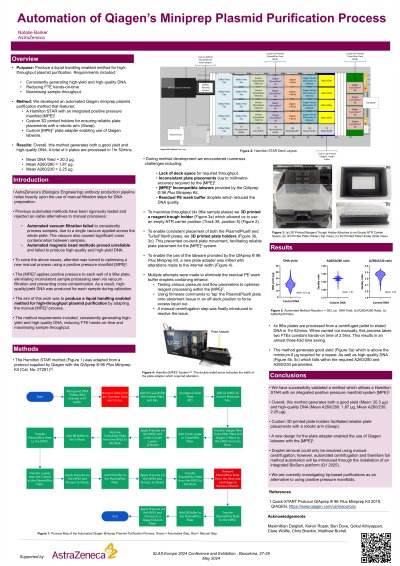

Poster Presenter(s)

Abstract: AstraZeneca’s (antibody production) pipeline relies heavily upon the use of manual filtration steps for DNA preparation. The aim of this work was to produce a liquid handling enabled method for high-throughput plasmid purification. The method requirements included, consistently generating high-yield and high-quality DNA, reducing FTE hands-on-time and maximising sample throughput. We have successfully validated a method which utilises a Hamilton STAR with an integrated positive pressure manifold system (MPE2). The method processes 4x 96w plates from a centrifuged pellet to eluted DNA in 1 hours 52 minutes. When carried out manually, this process takes two FTEs constant hands-on time of 2.5 hours to process 4 plates. This results in an almost three-fold time saving. Overall, this method generates both a good yield (Mean: 20.3 µg) and high-quality DNA (Mean A260/280: 1.87 µg, Mean A260/230: 2.25 µg). This method presented two main challenges. The first involved inconsistent labware placement, which was solved using 3D-Printing and a re-design of an MPE2 component. The second involved residual wash buffer droplets from the elution plate, which reduced the DNA quality. Droplet removal could only be resolved using manual centrifugation; however, automated centrifugation and therefore full method automation will be introduced through the installation of an integrated BioSero platform (Q1 2025).