Frontiers in Technology

Poster Session B

(1129-B) General structure of experiments for comfortable laboratory automation

Wednesday, May 29, 2024

10:30 - 11:15 CEST

Location: Exhibit Hall

Yuya Tahara-Arai, Bsc (he/him/his)

Graduate student

University of Tsukuba

Tsukuba, Ibaraki, Japan

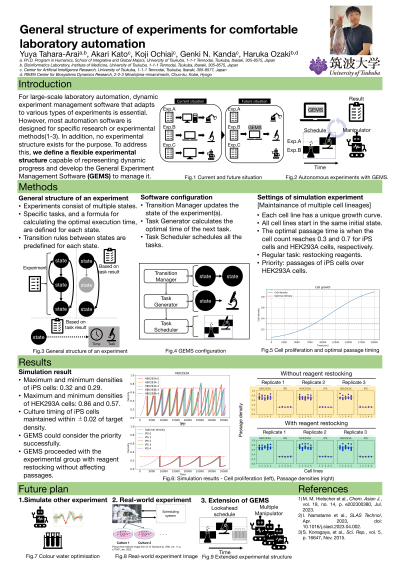

Poster Presenter(s)

Abstract: Current laboratory automation is uncomfortable. This is because it only considers limited automation situations. Automation of experimental procedures has stabilized quality, reduced costs, and enhanced efficiency in life science research. Many different automated experimental machines perform specific experiments and more sophisticated workstations or orchestration systems automate various kinds of experiments. The integration of dedicated hardware and software realizes these laboratory automation systems. However, specifications of the software tools for laboratory automation may confine the potential of laboratory automation. For example, structures dedicated to sequential experiments, such as cell maintenance culture, cannot deal with experiments involving branches and loops. This is because the general data structure of the experiment has not been standardized, so the structure of the experiment is defined as specific to the automation equipment. Without such standardization, large-scale laboratory automation that handles multiple experiments simultaneously is impossible. To solve this problem, we defined a general structure of experiments and developed a system which manages the progress of the experiment using the structure, which we named GEMS (General Experiment Management System).

GEMS is software that efficiently manages multiple types of experiments simultaneously. GEMS interprets experimental procedures as a directed graph structure and continuously performs dynamic scheduling of the experimental steps. Initially, we defined a general structure for experiments to handle various types of experiments.

The general structure of experiments is defined to manage various types. [1] Each experiment is composed of multiple states. [2] Specific tasks, such as 'Plate Coating,' are assigned to each state. [3] Additionally, each state has a formula that calculates the optimal execution time for its task, based on the results of previous states. [4] Transition rules between states are predefined for each state. [5] As the experiment progresses, the completion of tasks in the current state triggers the transition to the next state, which is determined based on the rule.

Subsequently, we developed GEMS to handle such a structure. We evaluated it using an automated laboratory simulator in a scenario where one general-purpose dual-armed robot cultured five cell lines each of iPS cells and HEK293A cells, with a regular temporal task (restocking of reagents). In this simulation experiment, we confirmed that GEMS could simultaneously manage multiple types of experiments, HEK293A and iPS cultures, and dynamically generate schedules that potentially allow collaboration with humans. This system contributes to the practical automation of experiments and is expected to play a crucial role in future laboratory automation.

GEMS is software that efficiently manages multiple types of experiments simultaneously. GEMS interprets experimental procedures as a directed graph structure and continuously performs dynamic scheduling of the experimental steps. Initially, we defined a general structure for experiments to handle various types of experiments.

The general structure of experiments is defined to manage various types. [1] Each experiment is composed of multiple states. [2] Specific tasks, such as 'Plate Coating,' are assigned to each state. [3] Additionally, each state has a formula that calculates the optimal execution time for its task, based on the results of previous states. [4] Transition rules between states are predefined for each state. [5] As the experiment progresses, the completion of tasks in the current state triggers the transition to the next state, which is determined based on the rule.

Subsequently, we developed GEMS to handle such a structure. We evaluated it using an automated laboratory simulator in a scenario where one general-purpose dual-armed robot cultured five cell lines each of iPS cells and HEK293A cells, with a regular temporal task (restocking of reagents). In this simulation experiment, we confirmed that GEMS could simultaneously manage multiple types of experiments, HEK293A and iPS cultures, and dynamically generate schedules that potentially allow collaboration with humans. This system contributes to the practical automation of experiments and is expected to play a crucial role in future laboratory automation.