Frontiers in Technology

Poster Session A

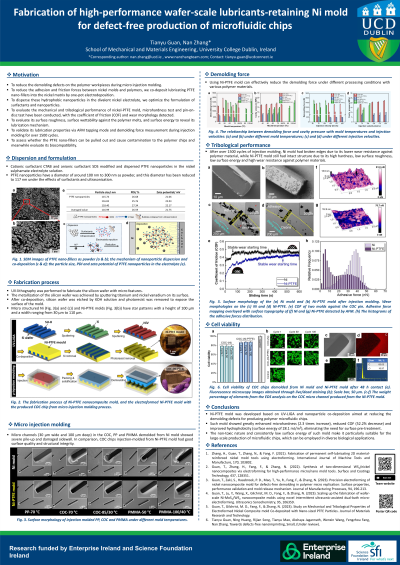

(1050-A) Nickel-polytetrafluoroethylene nanocomposite mould for defects-free micro injection molding/hot embossing of microfluidic devices

Tuesday, May 28, 2024

16:30 - 17:15 CEST

Location: Exhibit Hall

.jpg)

Tianyu Guan, PhD student in Engineering (she/her/hers)

PhD student

University College Dublin

Dublin, Dublin, Ireland

Poster Presenter(s)

Abstract: Polymer micro/nano replication serves as a versatile technique for crafting micro/nano devices and functional surfaces, catering to applications such as diagnostics in microfluidics, sensing in micro optics, and healthcare-oriented bioinspired surfaces with anti-bacterial and antiviral properties for food packaging. However, the fabrication of microscale moulds for these polymer devices can pose challenges due to potential damage from adhesion and friction between the polymer substrates and the mould. In addressing this concern, we have pioneered a novel technology involving the co-deposition of nano-sized polytetrafluoroethylene (PTFE) particles with nickel to enhance the lubrication properties and wear resistance of nickel micro moulds. Our experimental findings underscore the substantial role played by nano-sized PTFE particles in improving the lubrication, mechanical, and tribological properties of the composite moulds. The formulation of PTFE-surfactant was systematically studied, considering particle size and zeta potential. Utilizing the micro-electroforming process, we successfully fabricated a Ni-PTFE nanocomposite mould. Micro injection moulding using Polypropylene (PP, Sabic, 83MF10), Cyclic Olefin Copolymer (COC, TOPAS, 8007), and Polymethyl methacrylate (PMMA, ALTUGLAS VSUVT) validated the lubrication properties of the Ni-PTFE nanocomposite mould, ensuring the defects-free production of polymeric micro surface structures. This innovative approach holds promise for advancing the efficiency and precision of micro/nano replication techniques in diverse microfluidic applications.